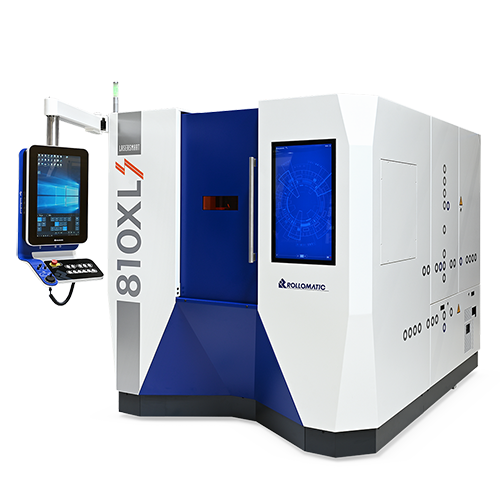

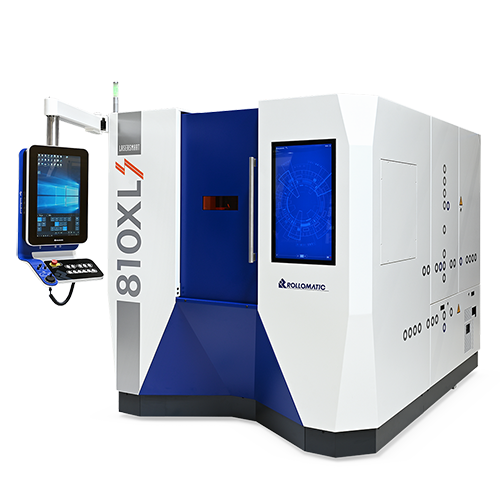

LaserSmart 810XL

Designed for the production of cutting tools in ultra-hard materials and featuring 6 simultaneously interpolated axes, the LaserSmart®810XL is ideally suited for machining tools up to 300 mm (12”) in diameter, 350 mm (14”) in length and up to 15 kg (33 lbs.) in weight. An automatic robot with a capacity of 30 parts is included as standard. The LaserSmart®810XL is the perfect solution for machining ultra-hard tools used in the automotive, aerospace and woodworking industries.

INNOVATIVE KINEMATICS

- Latest generation scanner offering high dynamics and precise positioning, resulting in a significant increase in productivity and unmatched process accuracy.

- Machine designed with innovative, very light and ultra-rigid materials in order to reduce moving masses and increase the rigidity of strategic elements.

- The laser and scanner are never set in motion, thus avoiding any transmission of vibrations.

- The Zp workpiece axis allows the tool to be positioned so that the part to be machined is close to the center of rotation of the B axis, thus reducing axis movements during interpolation to obtain very high precision and stability in production.