The 6-axis precision tool grinder GrindSmart®630XW has been designed for high performance and specialty tool manufacturing for both long and short batches. It is equipped with linear motors, combined with the torque motor on the rotary axis, provides more benefits such as enhanced surface finish and reduced maintenance costs. The oil used for cooling and lubricating the linear motors is the same as the coolant oil. This ensures consistent thermal stability during setup and production without incurring additional energy consumption.

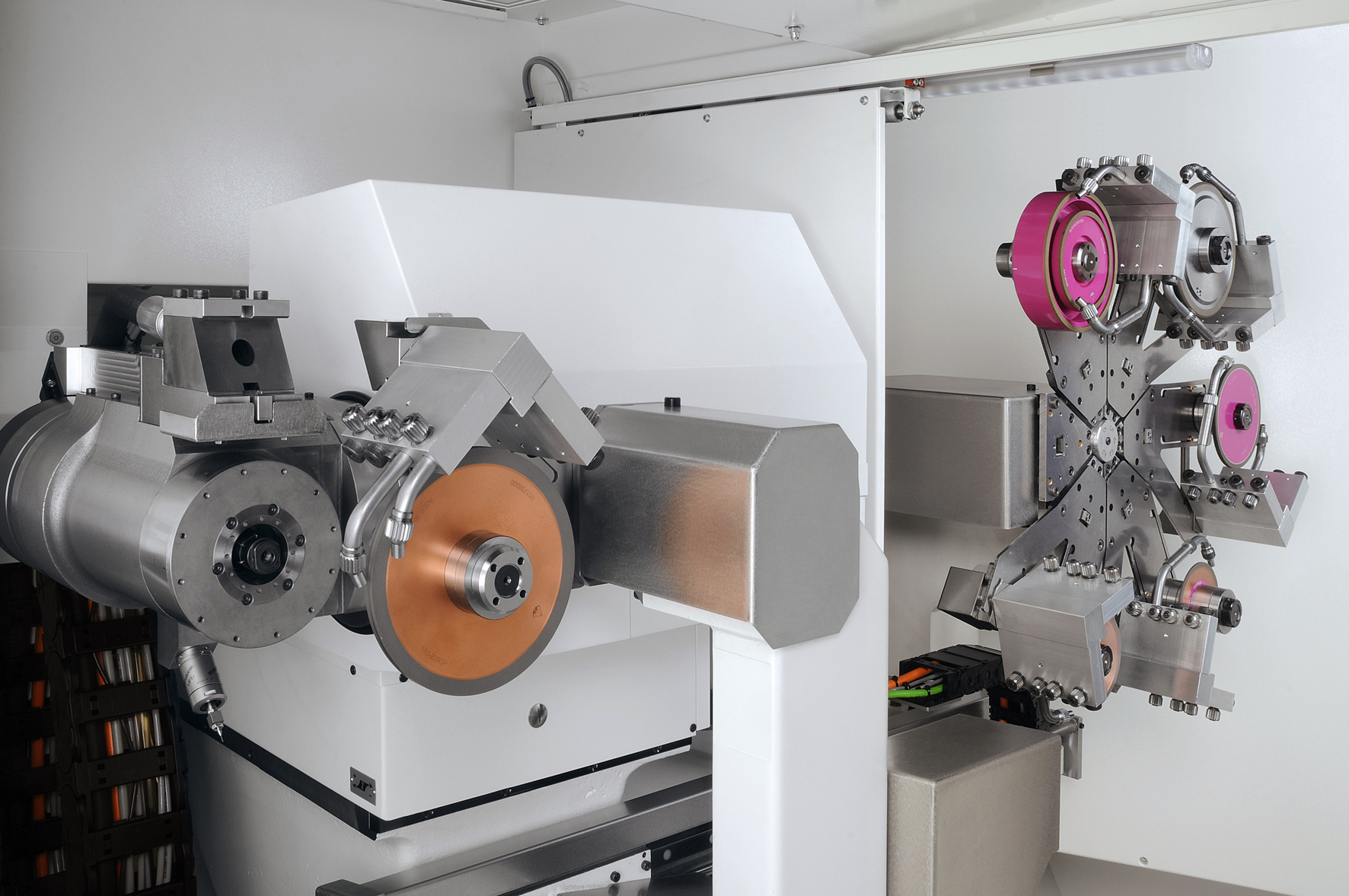

The 6th axis concept of this machine is unique in the grinding industry. It provides improved accuracy on ballnose endmills, or corner radii with a possibility to incline the grinding wheels and allows for easier programming with shorter empty moves during grinding operations. This machine covers a wide range of diameters from Ø 0.1 to 20.0 mm (.004" - .75"). As standard, this model includes automatic high speed pick & place tool loader with a capacity of up to 1,360 tools along with a high-speed wheel & nozzle changer with 6 positions.

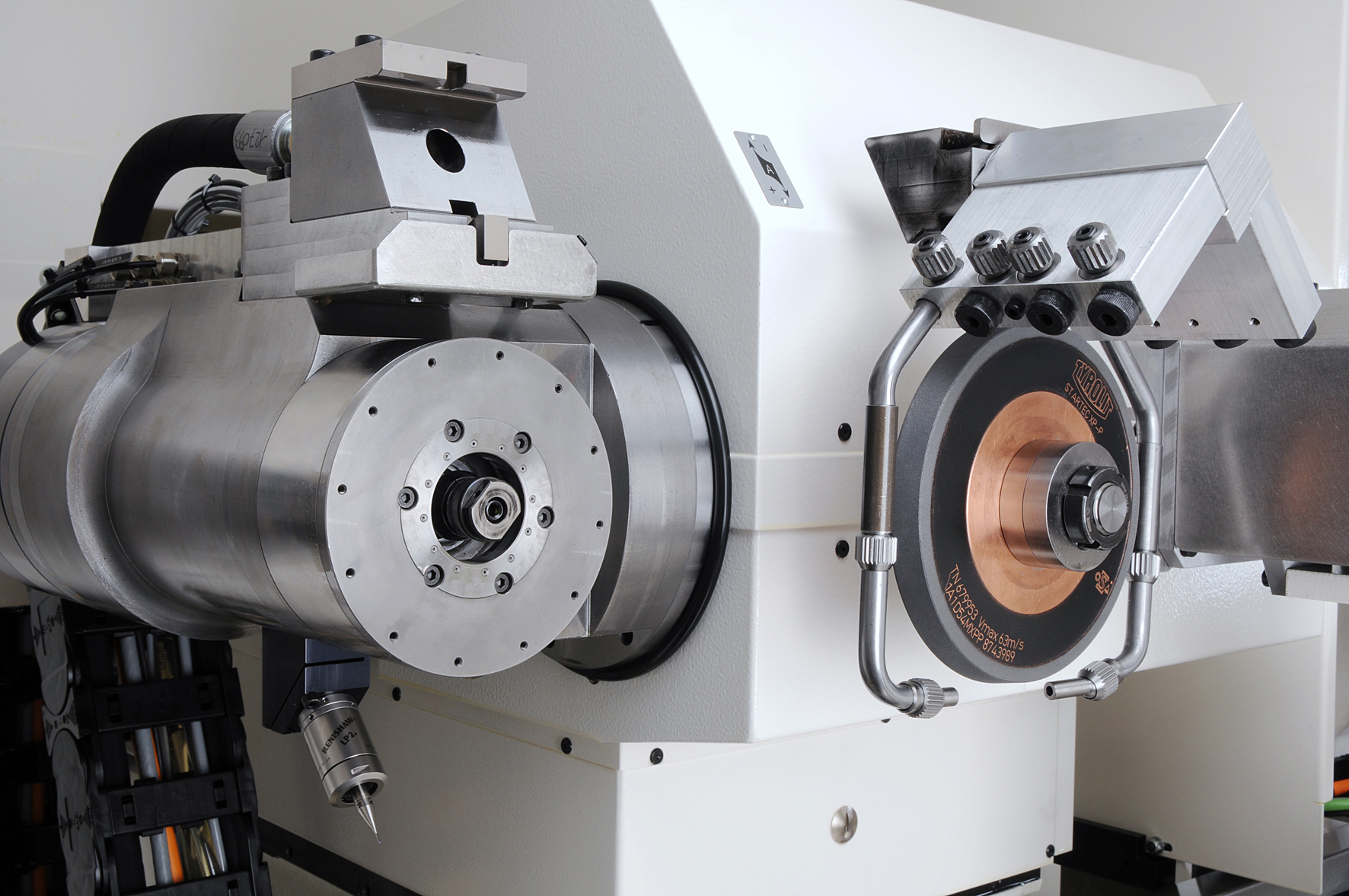

The ultra-efficient synchronous spindle motor on the 630XW3 and XW models provides constant rotation speed and torque regardless of the motor load. This technology offers the advantage to obtain perfectly consistent and high quality surface finishes, especially when the motor load is high.

This unique design of the new GrindSmart® series offers the greatest flexibility and reliability as well as an exceptional level of accuracy among all tool and cutter grinders on the market.

YOUR BENEFITS

- Typical productivity: 8,000 - 10,000 pieces per month

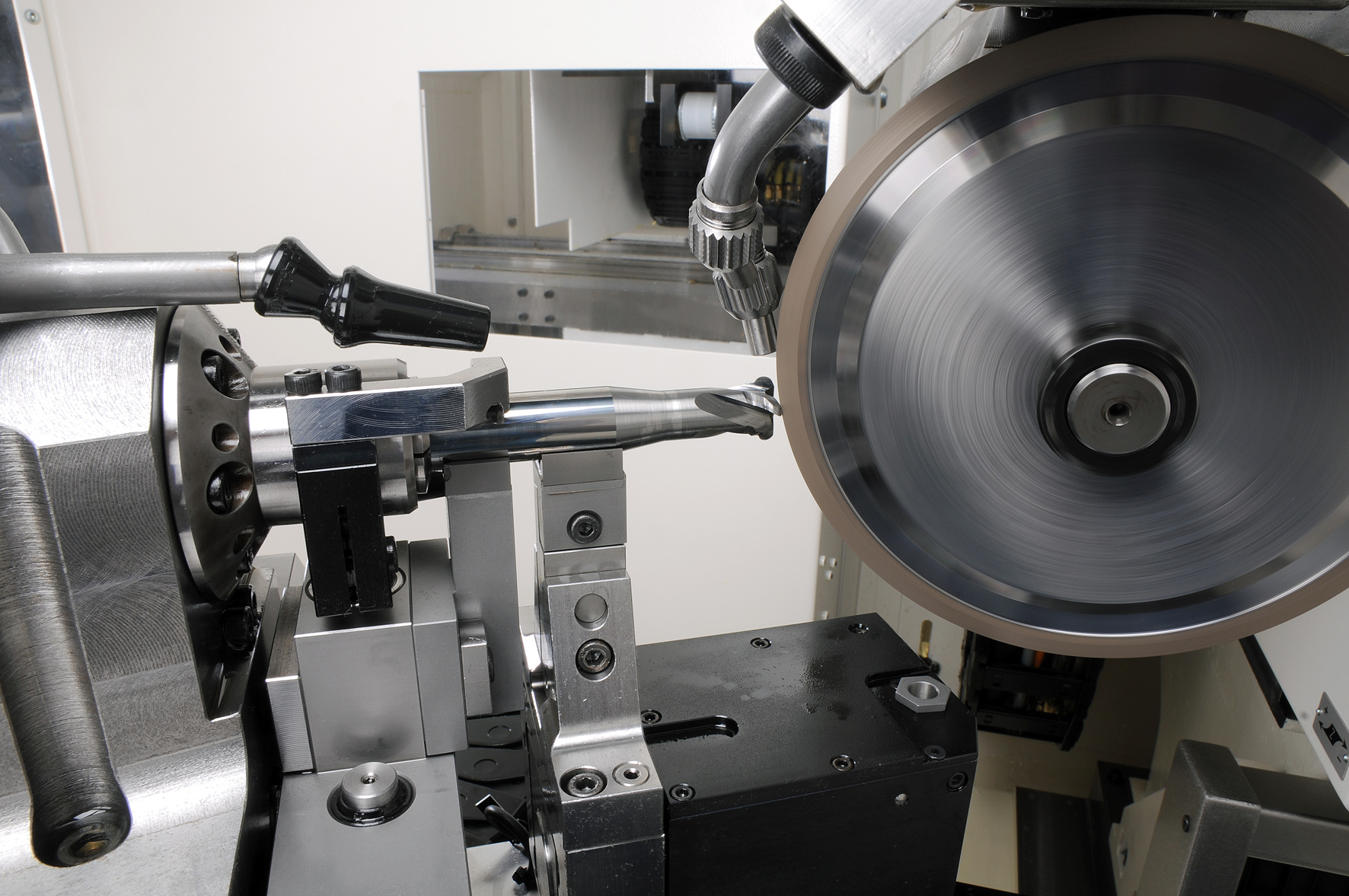

- Patented shank guide and steady rest support to reach a concentricity of less than 0.002 mm

- Short axis movements for greater stability and precision in production

- Linear and torque motors provide mirror surface finish

- JobManager software for unattended production of tools with different geometries

- Small footprint allows optimal use of available shop-floor space

- 6-axis kinematics for more flexibility and precision

- Enhanced productivity thanks to simultaneous changing of the wheel & nozzle packs during the tool loading/unloading cycle

- High-performance synchronous spindle and redesigned HSK50 attachment provide consistent and high quality surface finish

- Unique grinding capacity enables production of micro tools and large diameter tools all with the same machine

APPLICATIONS

With its 6-position wheel changer and a 6th axis that allows tilting of the grinding spindle as a fully interpolating axis makes the GrindSmart®630XW the most flexible machine on the market.

In addition, the synchronous spindle motor developing a power of 14kW offers the possibility of grinding an exceptionally large diameter range, either for micro-tools and other 20 mm diameter applications.

All these features make the GrindSmart®630XW the ultimate universal machine and will allow you to produce end mills, drills, interchangeable inserts, boring bars, taps, thread mills, engraving cutters, dental and surgical tools and much more.

Successfully and widely used in various industries such as mobile telephony, watchmaking, automotive, aerospace, dental and surgical, and precision engineering, this machine stands out with its exceptional quality of surface finish and geometric accuracy of the ground parts.